Come parte dei nostri nuovi aggiornamenti di sicurezza, ti chiediamo di reimpostare la password

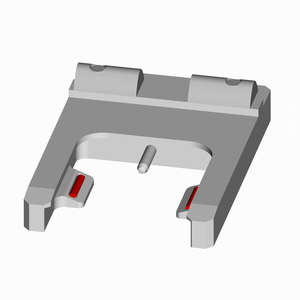

CMM

ID: I00000005

Prezzo:

CHF424.35

In giacenza - Spedizione in 1-2 giorni

ID: H007626

Prezzo:

In giacenza - Spedizione in 1-2 giorni

ID: GB0122-0008

Prezzo:

CHF560.00

In giacenza - Spedizione in 1-2 giorni

ID: GB0122-0019

Prezzo:

CHF480.00

In giacenza - Spedizione in 1-2 giorni

ID: 03969394

Prezzo:

CHF3,290.00

In giacenza - Spedizione in 1-2 giorni

ID: 03969391

Prezzo:

CHF940.00

In giacenza - Spedizione in 1-2 giorni

ID: 03969363

Prezzo:

CHF1,720.00

In giacenza - Spedizione in 1-2 giorni

ID: 03969365

Prezzo:

CHF325.00

In giacenza - Spedizione in 1-2 giorni

ID: 03969366

Prezzo:

CHF408.00

In giacenza - Spedizione in 1-2 giorni

ID: 03969367

Prezzo:

CHF499.00

In giacenza - Spedizione in 1-2 giorni

ID: 03969392

Prezzo:

CHF940.00

In giacenza - Spedizione in 1-2 giorni

ID: 03969065

Prezzo:

CHF226.00

In giacenza - Spedizione in 1-2 giorni

ID: 03969067

Prezzo:

CHF300.00

In giacenza - Spedizione in 1-2 giorni

ID: 03969066

Prezzo:

CHF263.00

In giacenza - Spedizione in 1-2 giorni

ID: 03939302

Prezzo:

CHF1,030.00

In giacenza - Spedizione in 1-2 giorni

Aggiunto al carrello.

Disponibilità dei prodotti per sede del negozio

Ore