testing

€5,270.00

Vue d'ensemble sommaire

SWIFT-CHECK is an interim testing artefact, which enables the machine operators to regularly check the performance of any small to mid-size coordinate measuring machine in a few minutes.

With the SWIFT-CHECK interim testing artefact, CMM operators can perform quick and simple checks about the current performance of the machine. It delivers clear and easy results, giving operators the assurance they need to confidently perform further measurements with indexing probe heads, touch trigger probes and scanning sensors.

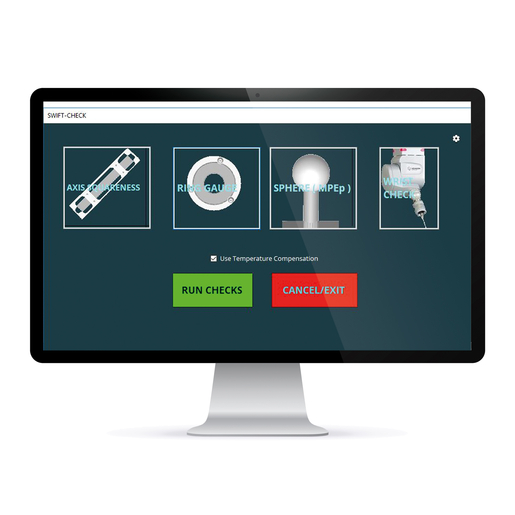

Swift-Check performs different routines to check the machine's current performance:

- Length check: Measures linear repeatability for each orientation and evaluates squareness of the CMM axes in each measuring plane.

- Ring check: Measures diameter and circularity of the ring gauge by either single points or a scan.

- Sphere check: Measures 25 points and evaluates the form and size errors related to the maximal permissible probing errors.

- Wrist/- / Probe head check: Measures 25 points on the sphere with each of the wrist calibrated positions.

All checks are displayed either as a PASS/FAIL statement or presented in a .CSV file and a standard PC-DMIS or QUINDOS report.

Delivery Contents:

- SWIFT-CHECK frame

- Length bar (L = 300 mm)

- Ring gauge (D = 25 mm)

- Sphere (D = 25 mm)

- Styli and adapters

- Calibration certificates

- Software (PC-DMIS or QUINDOS measurement routines)

- User guide

- Flight case

| CMM Compatibility |

GLOBAL S GLOBAL Lite TIGO SF 4.5.4 SF 7.10.7 SF |

|---|---|

| Software Compatibility |

PC-DMIS (V2016 onwards) QUINDOS (Q7R18351 onwards) |

| Run Time |

Length Check: 20 Minutes Ring Check: 5 Minutes Sphere Check: 5 Minutes Wrist- / Probe Head Check: 10 Minutes |

| Artefacts Dimensions |

Length Bar Length = 300 mm Ring Gauge Diameter = 25 mm Sphere Diameter = 25 mm |

| Matériau | Anodized Aluminium |

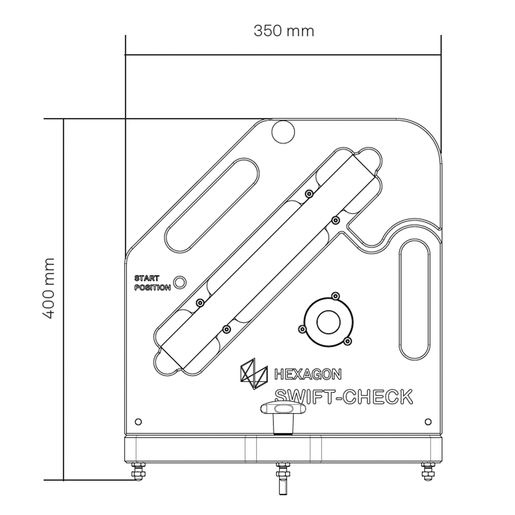

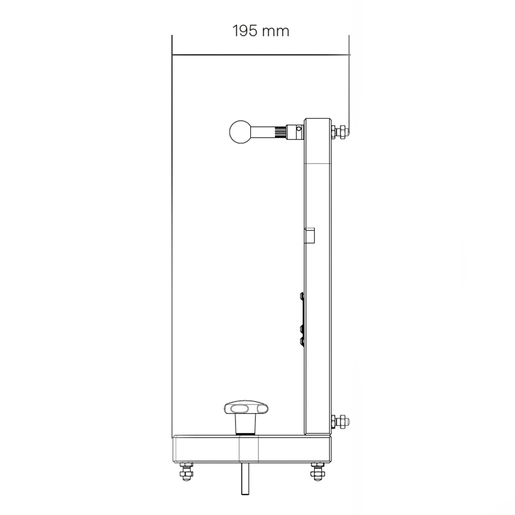

| Taille | 350 x 400 x 195 mm |

| Poids | 11 000 g |