Fixtures play a key role in ensuring the accuracy, speed and repeatability of a measurement process. Swift-Fix, Hexagon’s fully modular part-holding and fixturing system for CMMs and vision systems, are simple and easy to use, facilitating fast, accurate part measurement with many benefits.

Rapid Set-up

Operators simply screw the components into the base plate. Swift-Fix’s flexibility makes it possible to further reduce setup time by putting several parts on one base plate and running separate measurement routines in succession.

Repeatability

Alphanumerical labelling on the base plates makes it easy to record a fixture and quickly set it up again when needed.

Accessibility

Measurement speed depends on sensors having free access to a part during the measuring routine. Swift-Fix offers a variety of clamping methods and standoffs to minimise contact between the fixture and the part and maximise its accessibility from all sides.

Flexibility

Swift-Fix allows for a wide range of configurations in one kit. Furthermore, operators can alter a fixture configuration in just a few moves. No matter how complex the component to be measured, Swift-Fix is flexible enough to adapt quickly to changing needs. Swift-Fix enables clear measurement paths by maximising accessibility and minimising contact between the part and the fixturing.

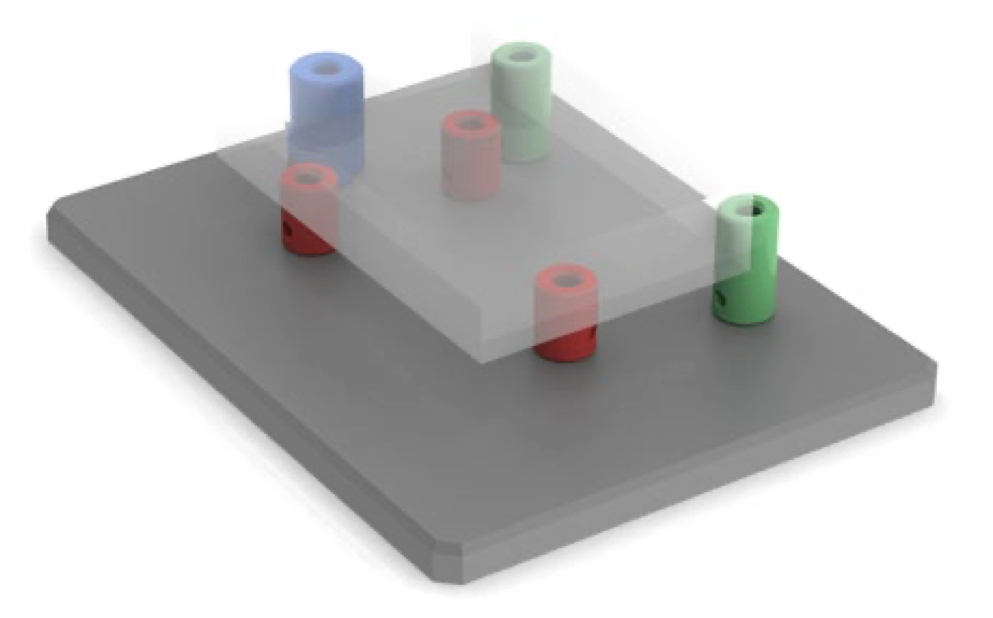

The 3-2-1 principle is the foundation of successful fixturing. When fixing the first axis, three setting points provide the stability for accurate plane measurement (in red in the diagram).

For the second axis, two points set the component line direction (in green). And for the third axis, one point sets the datum (in blue).

Four tips for fixturing confidence

1. Ascertain where you want to take measurements on the part before building the fixture so you can maximise access for sensors.

2. Ensure the security of your fixturing by tapping the part with your fingers from all directions to make sure it is stable enough. You’ll find that overtime, with a trial and error approach, you’ll be able to remove as many components as possible while ensuring fixturing stability (saving you time and driving efficiency).

3. Keep in mind that the measurement position doesn’t have to reflect how the part will be used. For example, a car door can be measured horizontally, but assembled vertically.

4. Only use tools if needed. Often tightening components by hand is enough. Secure the part against the desired measurement direction. The only force that should impact the part is the force from the sensor. You should make sure that the part can’t slip in this direction.

Ready to make secure measurement smarter? Find the right Swift-Fix part-holding and fixturing system for your application needs here.